Project Overview

An Augmented Spark Igniter (Torch Igniter), is a typical ignition source used in industry-level liquid propulsion rocket engines. This project is used as a clean slate for us to start implementing a true-to-form engineering design process going from design, design review, revision, build, test, revision, and implementation. Furthermore, starting small scale will allow us to test with real propellants with Yale Environmental Health & Safety.

Your Role and Contributions

- As Avionics & Control Lead, I had to present a Preliminary Design Review outlining what my initial design would be relating to an ASI Driver. This design review would be presented to the stakeholders including Yale EHS, our mentor from Vast Aerospace, our direct mentor, and chief engineers.

- I had to communicate with other subteams to outline my design requirements for an Avinoics System and also guage other design requirements to know what valves are needed, what sensor data we need, and obtain a state diagram for what stae the ASI can be at any point in time during a test.

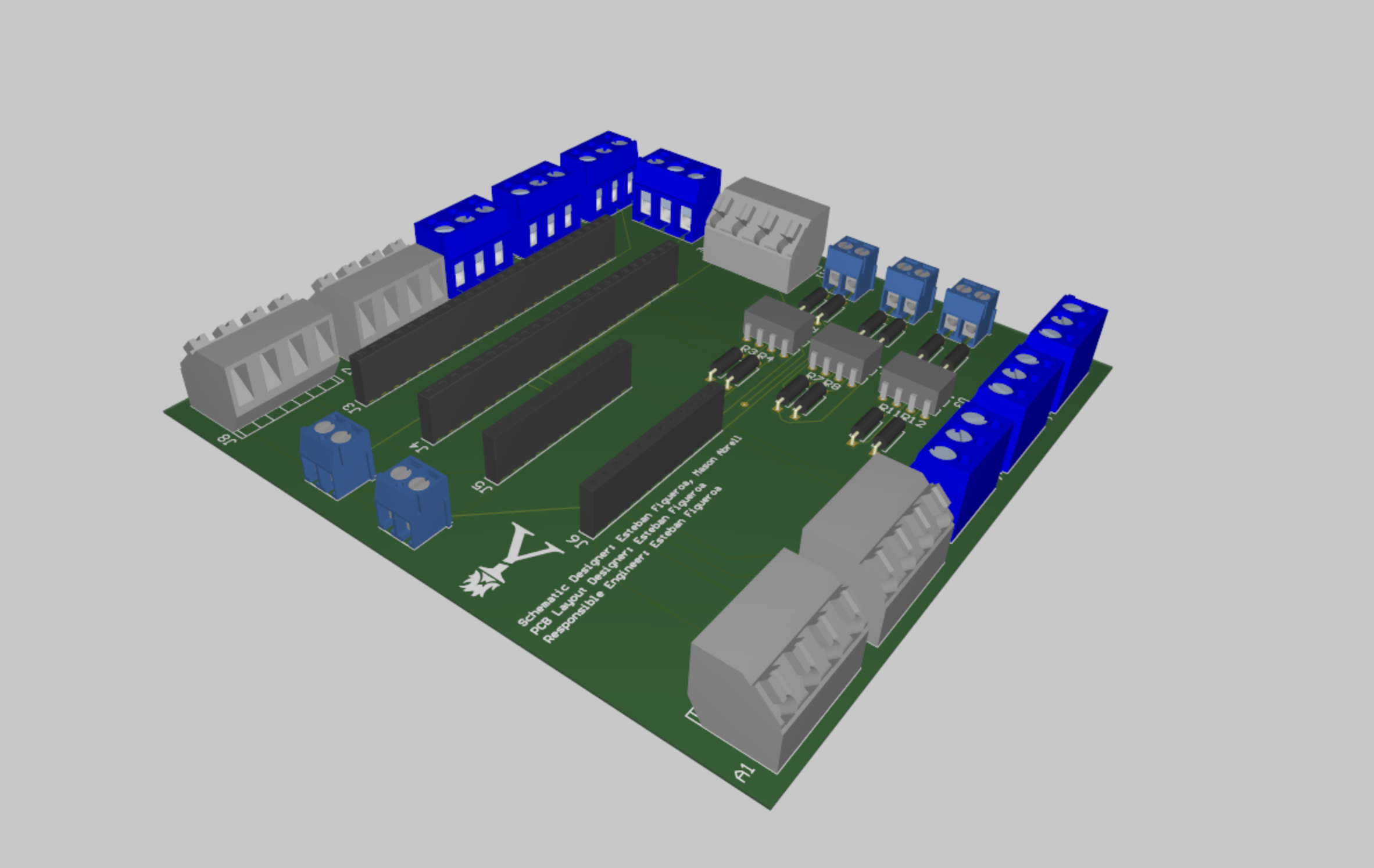

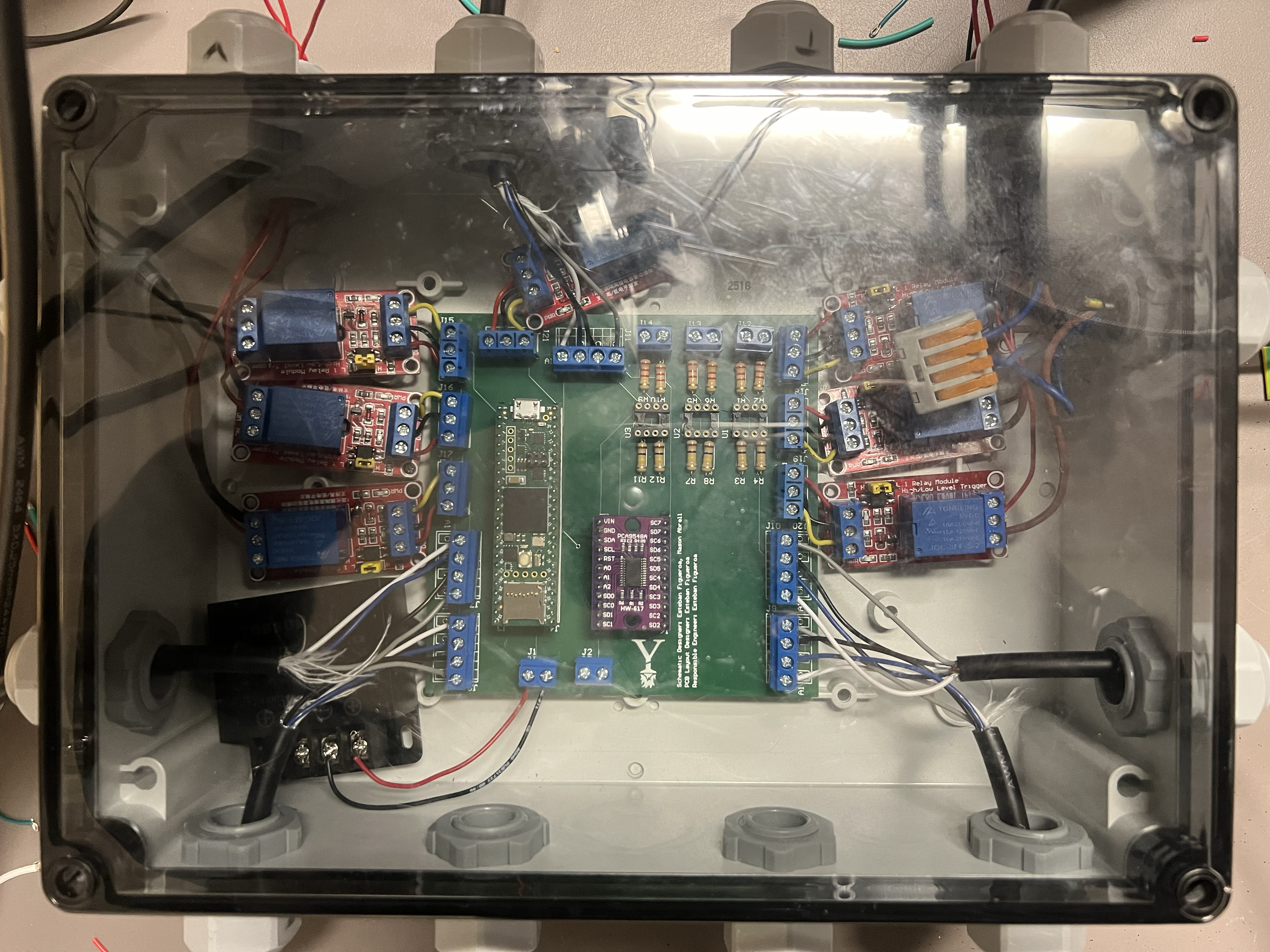

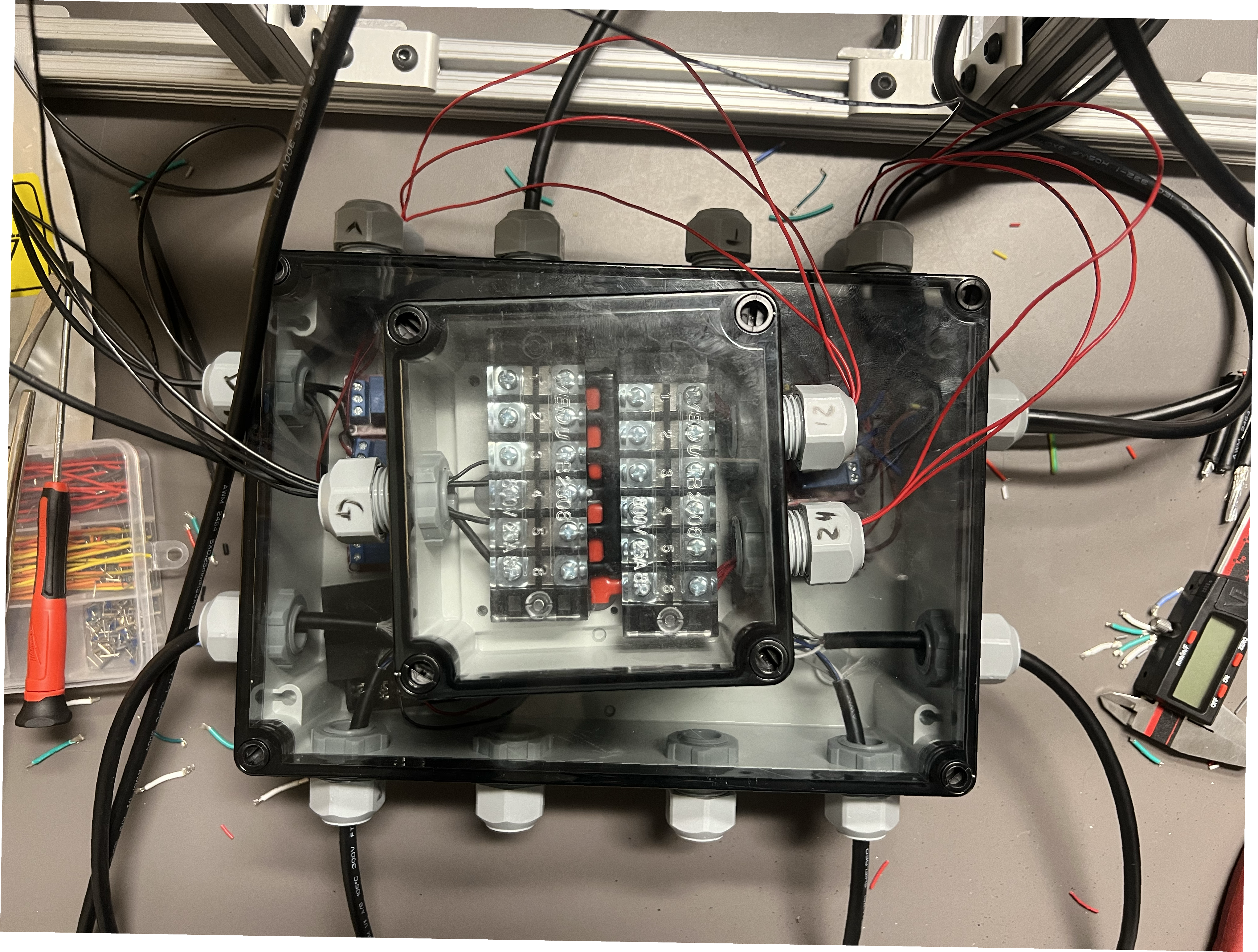

- I designed a new PCB based off of our old Water-Flow test designs, still employing the use of an I2C multiplexer since we upgraded our pressure transducers but still make use of I2C. All of our valves now used DC current so I implemented 2 12V DC batteries in series, with a tap-off at 12V and 24V. To distribute power to every relay, valve, and spark plug, I used 3 screw-terminal buses, 1 for 12V, 1 for 24V, and 1 for ground. I upgraded the previous Arduino Mega to the Teensy 4.1 due to its increased number of pinouts, more versatility for each pin, ethernet capability, and increased processing speeds. As opposed to using a long USB cable like we did last year, I implemented aethernet capability for faster data transmission. Additionally, I implemented an Emergency Stop method for powering off the system in case of emergencies to adhere to EHS concerns.

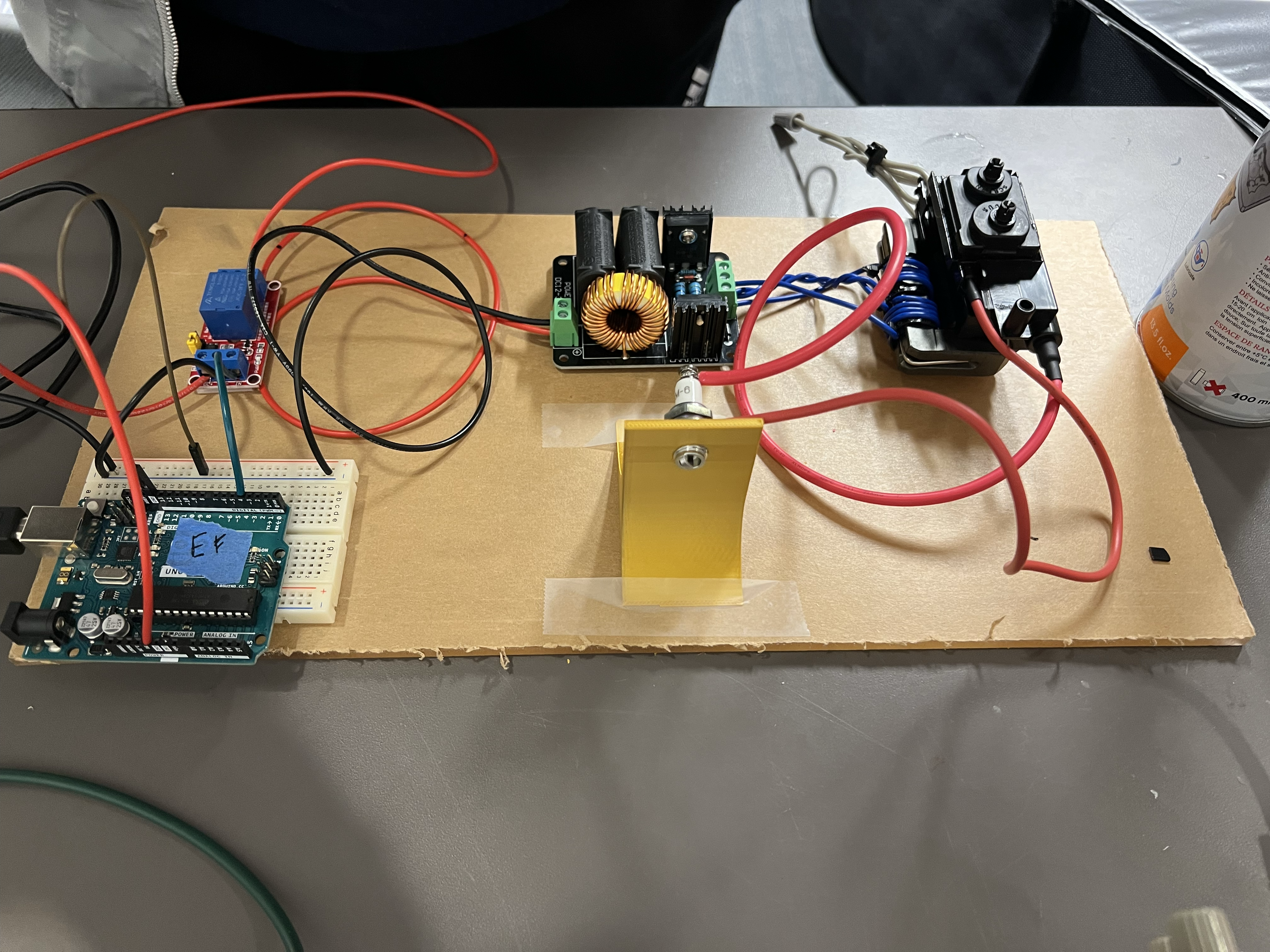

- With the help with our mentor from Vast, I implemented a Spark Plug Ignitiion System using a Zero-Voltage Switcher Driver and Flyback Transformer, which would be actuated with a relay similar to the valves.

- I parallel programmed with the programming team to develop a Graphical User Interface (GUI) which would actuate certain stages of a test at the push of a button with additional features which would allow to overwrite in case of emergencies. Additionally, the GUI would allow for real-time pressure readings. This data would then get exported into a custom data format for post-processing.

- I performed the data preparation, post-processing, analysis, and visualization for interpretation by the fluids team.

Skills and Tools

- Altium

- PCB Layout Design

- Circuit Analysis

- C++ Programming

- Python Programming

- Data Analysis and Visualization

- Project Management

- Debugging

- Presentation

- I2C

Goals and Objectives

- Fire an ASI for 1, 1.5, and 3 seconds.

- Collect data to characterize O/F ratios and their impact on our system and ignition potential.

- Demonstrate to Yale EHS of our safe handeling of propellants and attention-to-detail when it comes to procedures.

Outcomes and Achievements

Visual Aids

3D model of ASI Driver

Engine controller PCB inside NEMA box

Power buses inside NEMA box

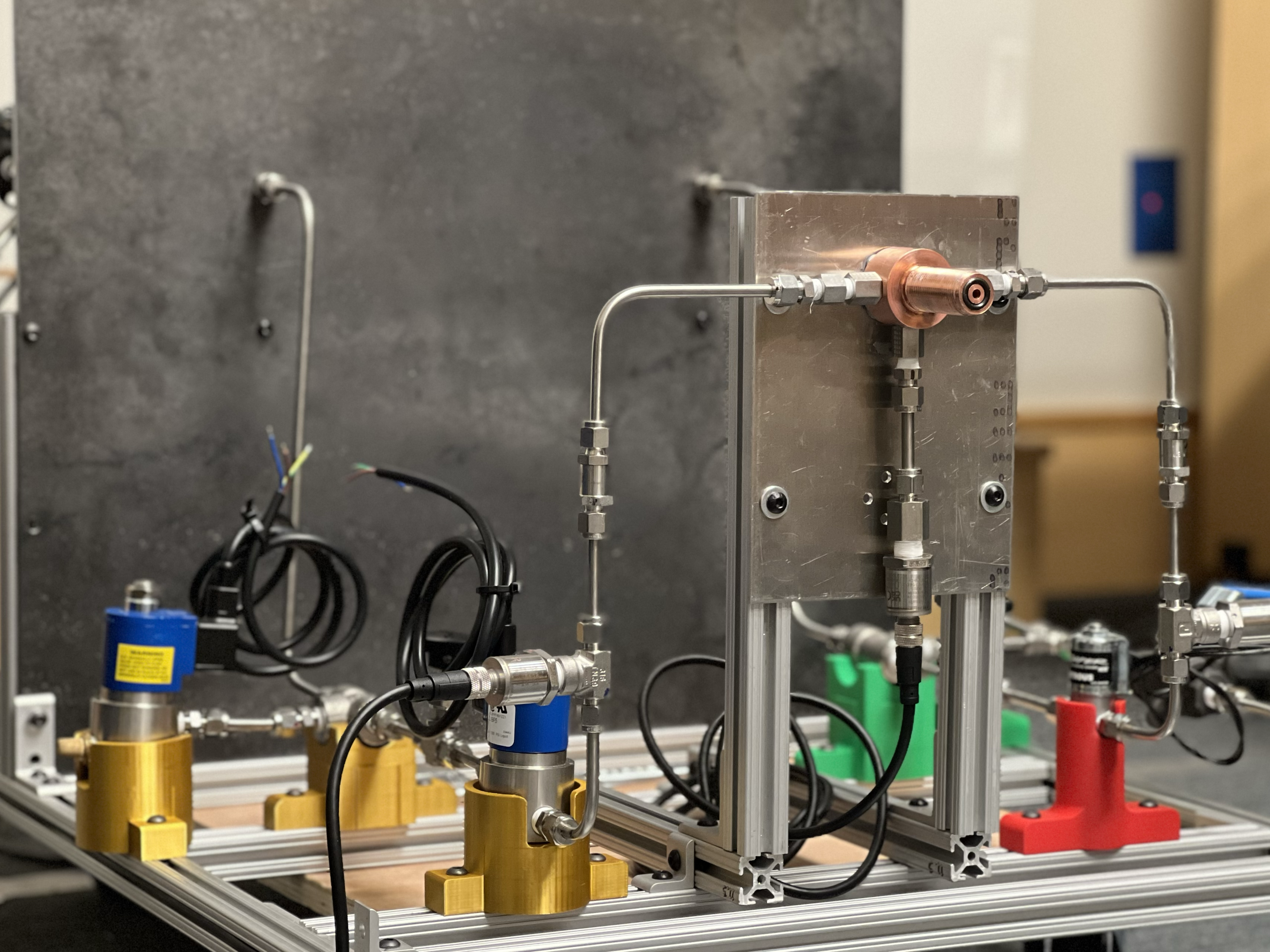

Image of the ZVS Driver, Flyback Transformer, spark plug, relay, and Arduino testbench

Isometric view of the ASI test stand

Team photo after successful fire

Video of testing the ZVS + Flyback for spark plug ignition

ASI Driver V1 Schematic

ASI A&C Preliminary Design Review

ASI A&C Critical Design Review

ASI A&C Build Readiness Review

Lessons Learned and Technical Takeaways

- I notice that everytime the spark plug ignites, all the sensors glitch and cause the live sensor readings to go dark. Additionally, the Teensy 4.1 would go dark in general, this happened until I covered the Ethernet port connected to the Teensy in tin foil to act as a faraday cage. This meant that the spark plug is probably emitting enough Electromagnetic Interference (EMI) directly into the sensors.

- When trying actuating the spark plug with propellant flowing through, there is, most of the time, no ignition, so there must be an issue with either the O/F ratio or the spark plug itself.

- When the Teensy 4.1 is running off its own power supply, the Teensy cannot actuate more than 2 relays at a time, i.e. if we try to actuate a third, all the relays shut off. This indicates too much current is being pulled by the relays and the pins off the Teensy so a better way to actuate the valves will be needed.

Future Work

- Design and implement a new valve actuation actuator which a Teensy 4.1 can run on standalone power.

- Research EMI prevention techniques, trade study between digital and analog sensors in a noisy environment.

- New PCB design with more robust connectors than screw terminals, better grounding architecture, and protection against EMI.