Project Overview

As we start our first project for Yale Project Liquid (YPL), Yale's first liquid propellant rocket engine team, we have to prove our competency when it comes to designing an engine and handling high-pressure fluids in any environment. This Water Flow test is a proof of concept to Yale Environmental Health & Safety (EHS) that as college students, we can successfully design a rocket engine system, handle high-pressure fluids safely, implement safety precautions into our system, and overall design a system which works with minimal human troubleshooting and keeping everyone safe.

Your Role and Contributions

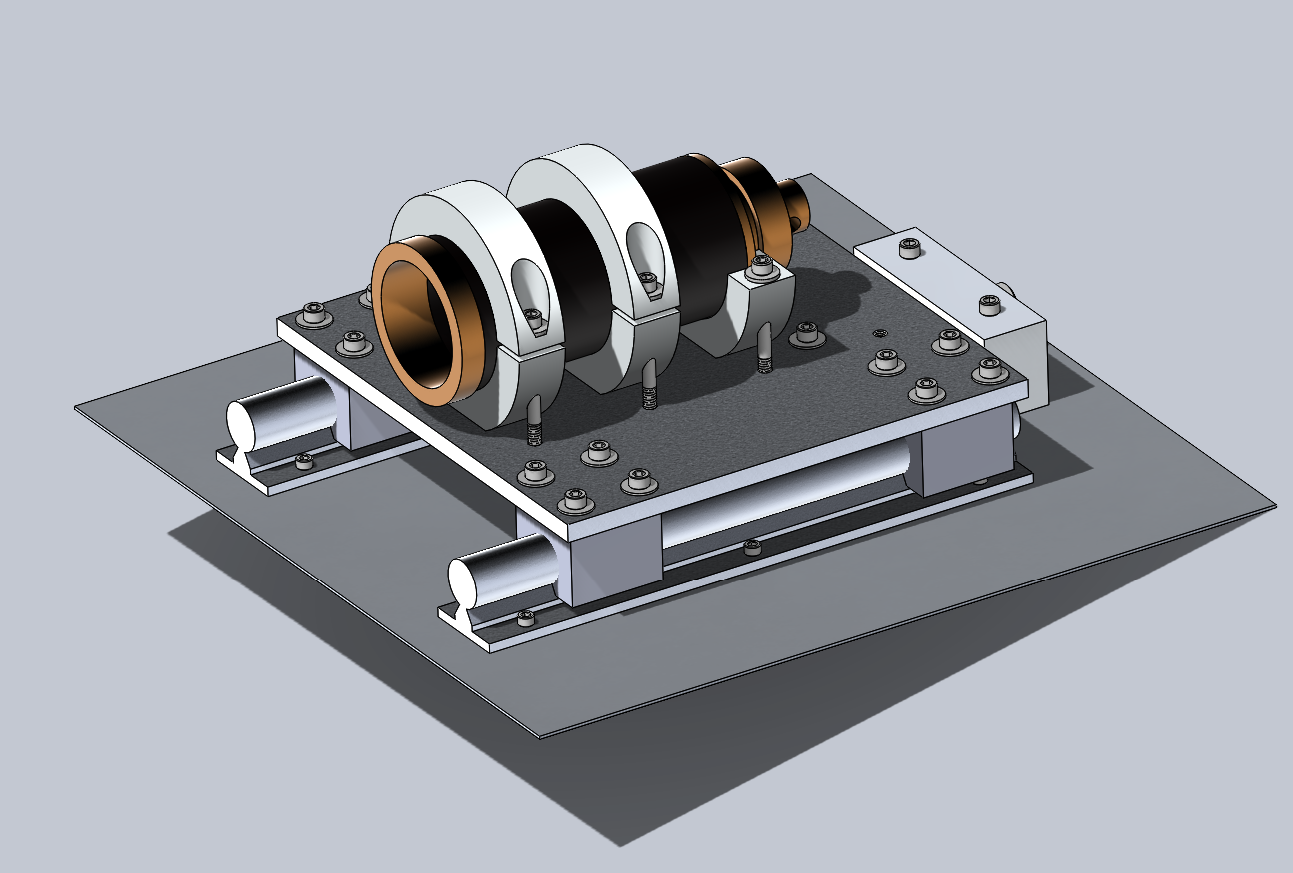

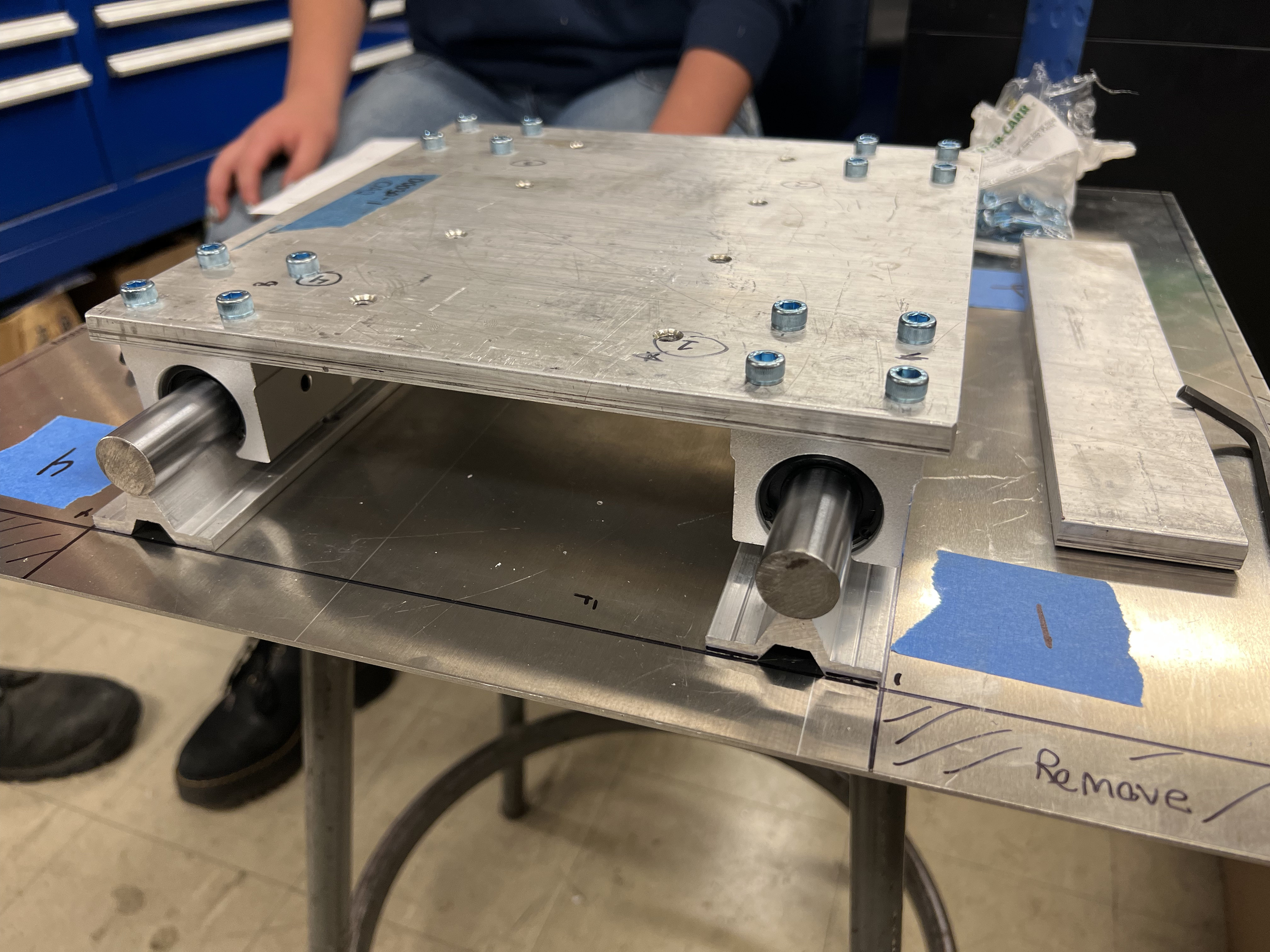

- I built a sliding plate assembly which was meant to measure thrust from the engine using a load cell. This involved taking measurements machining a thick plate of aluminum, mounting onto sliding rails, and attaching and wiring a load cell in such a way which would take accurate measurements.

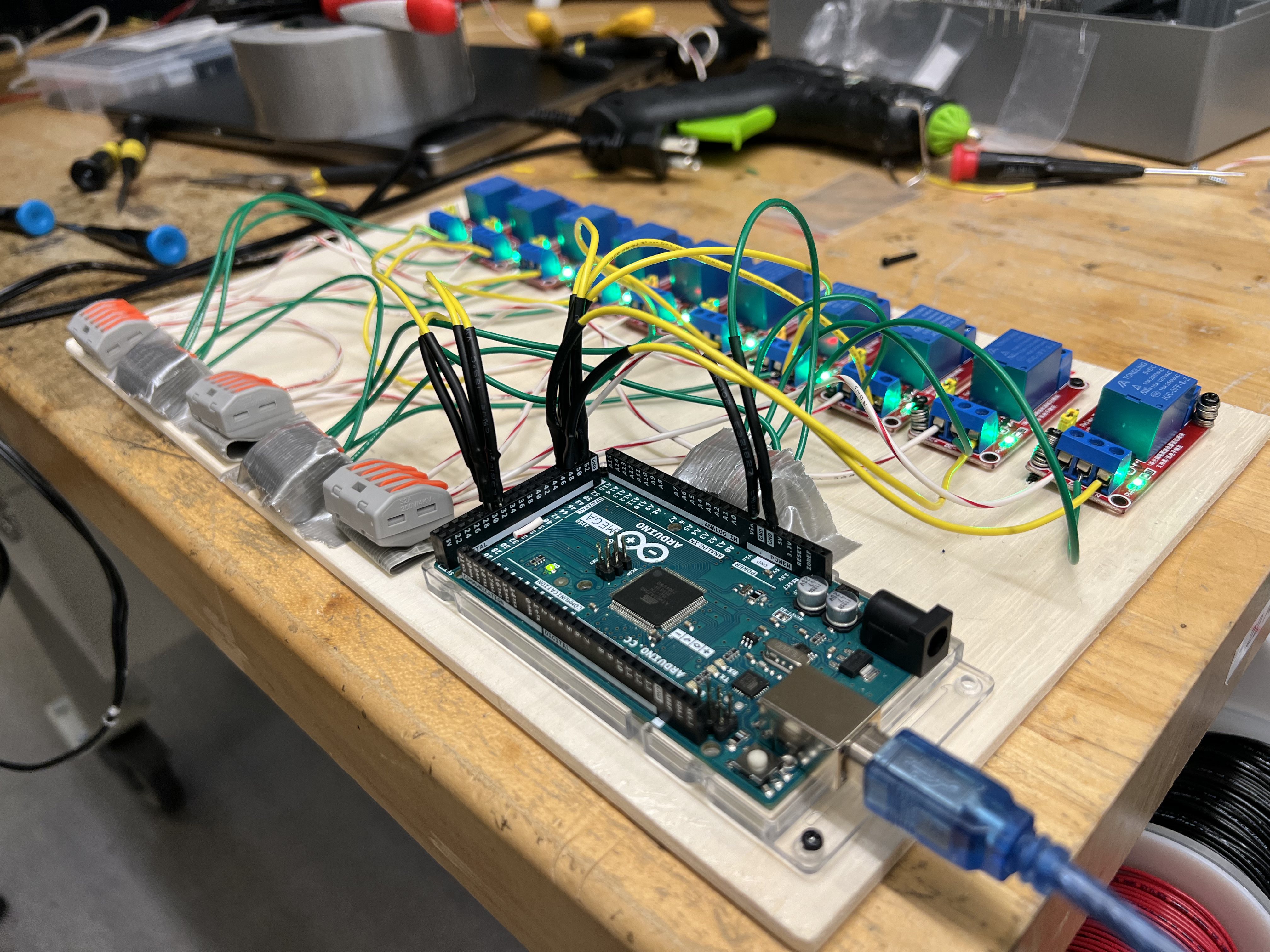

- I had just started taking electrical engineering courses at Yale when I joined, so I built upon the knowledge of the people before me to build an engine driver which was composed of multiple mechanical relays to drive valves varying from 12V DC, 24V DC, and 120V AC.

- I worked with the digital pressure transducers that we had on hand and implemented an I2C multiplexer which would allow us to multiplex multiple I2C pressure transducers to an Arduino Mega. This Arduino would also actuate the valves.

- I communicated with the fluid supply team to come up with a state diagram which would guide how to program the engine to react at different points of a test.

- I parallel programmed with the software team to write the sensor readers and valve actuation code.

Skills and Tools

- Systems Engineering

- Electrical Design

- Arduino Programming

- I2C

- Python Programming

- Data Analysis and Visualization

Goals and Objectives

- Successfully design, build, test, and operate a bi-propellant pressure-fed liquid rocket engine.

- Prove to Yale EHS competency in best and safe practices for mechanical and electrical design, and safe high-pressure fluids handling.

- Characterize the system in terms of pressure at different points of the routing.

Outcomes and Achievements

- We were successfully able to water-flow our system.

- The test resulted in talks with EHS of using Nitrous Oxide and Isopropyl Alcohol as our oxidizer and fuel.

- We were able to obtain viable data to study the flow of fluids inside the system.

Visual Aids

Rendition of thrust measurement assembly

Load cell and rails attachment

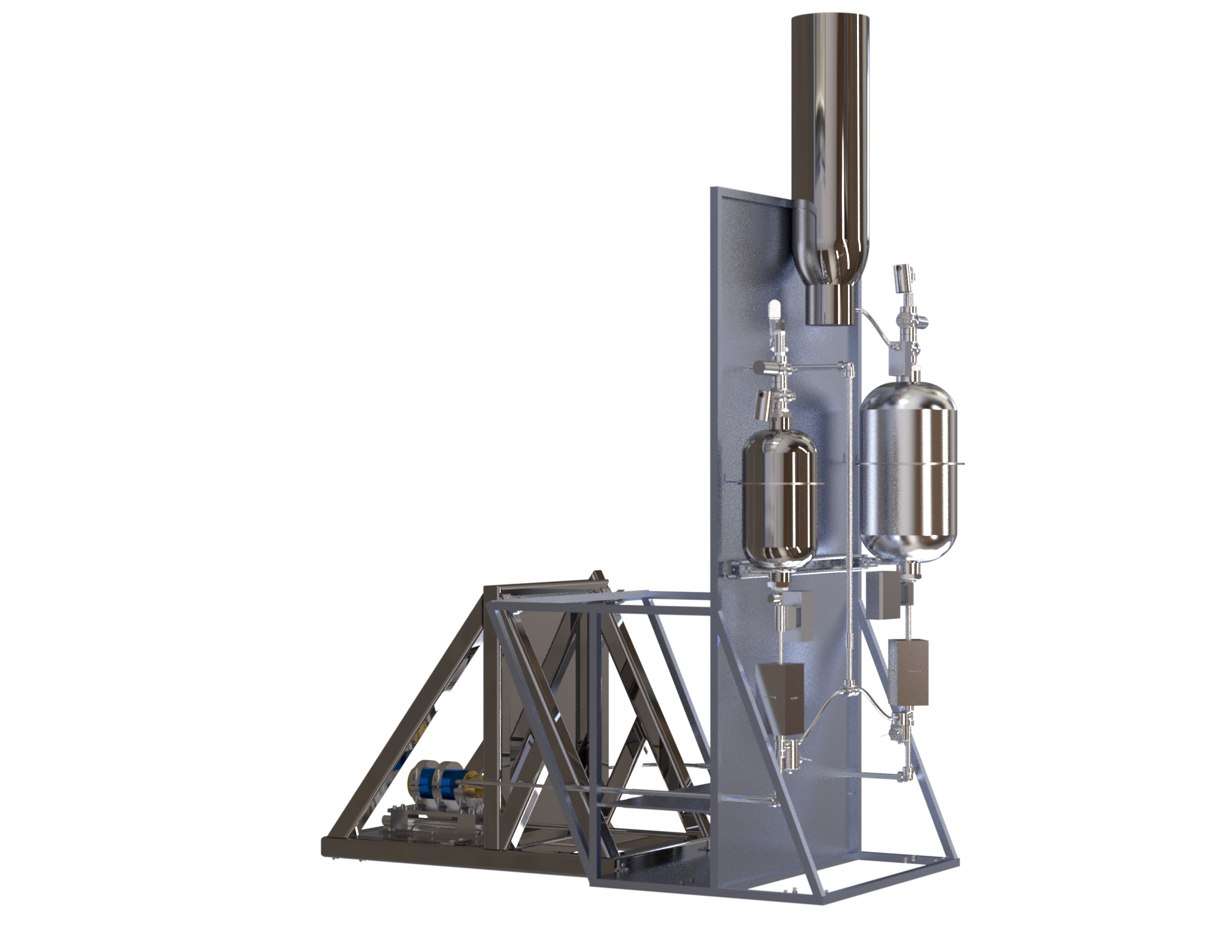

Test stand rendition (front)

Final build of sliding plate

Engine controller, relays for valves, Arduino Mega, screwed down to wood

Test stand rendition (back)

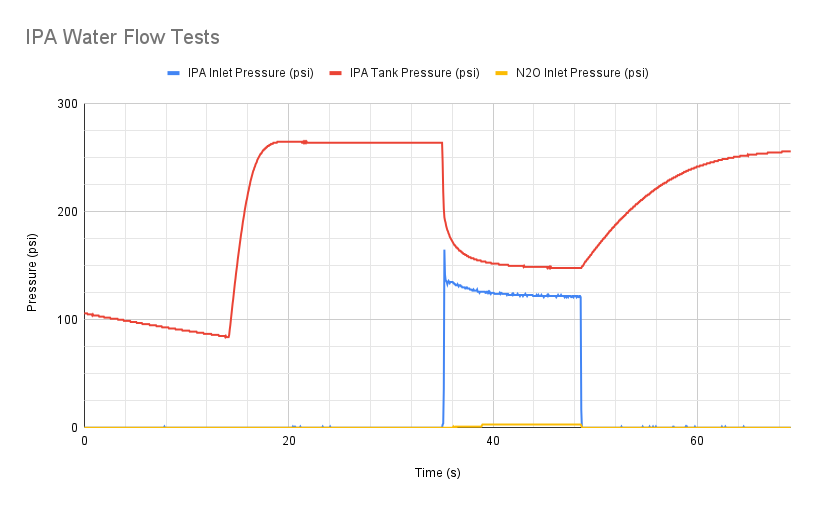

Water flow test through IPA lines

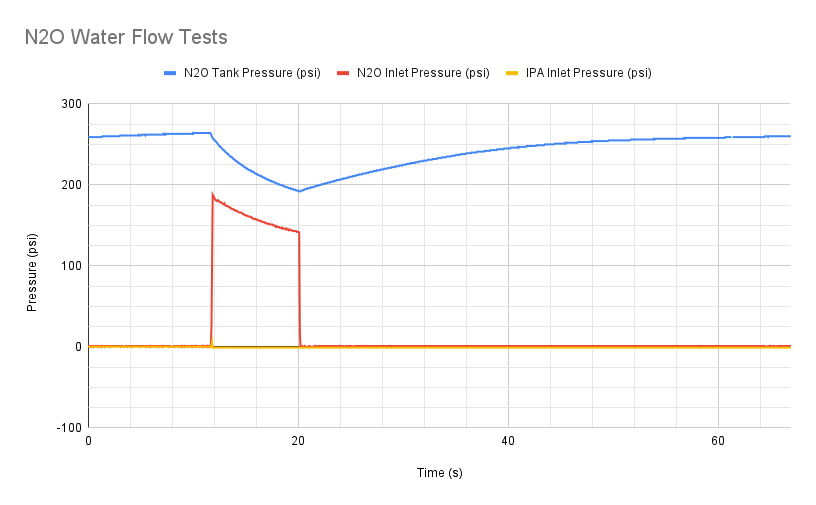

Water flow test through nitrous oxide lines

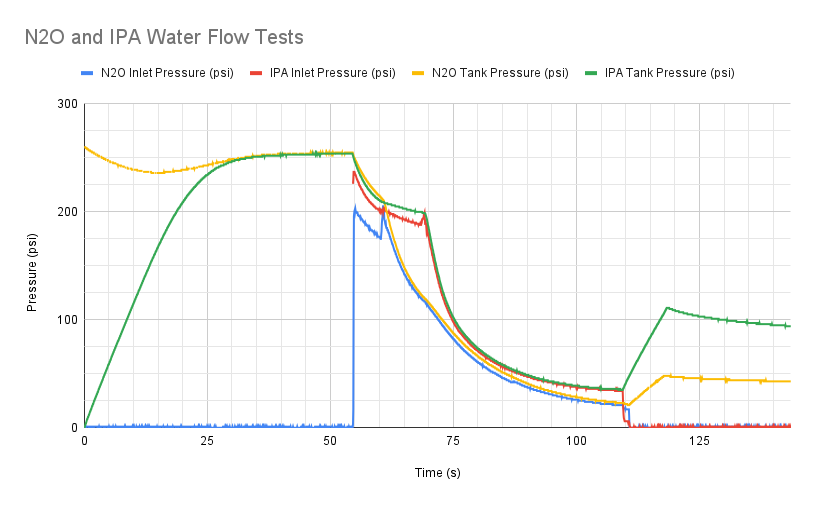

Full water flow test

Summary of our water flow test. Video courtesy of Jonah Halperin, Yale '26.

Lessons Learned and Technical Takeaways

- Flying wires are not ideal, it is more reliable and safest to have no tangled up wires.

- This enclosure is unideal since we are screwing down parts, it might be good to get a NEMA-rated box for enviromnetal protection.

- As a first-time rocket team, we bit off more than we can chew and compartmentalization might do us well as a learning experience and overall more robust engineering project.

Future Work

- Now that we have developed ourselves, the next step is build an Augmented Spark Igniter to work with real propellants. This will also allow us to start small and be very intentional with every design decision.

- Use the same parts but upgrade to a PCB, this will allow for more robust connections. Use ferules as well for screw-terminal connections.

- Obtain a an insulated enclosure for electronic parts.

- Move away from multi-voltage multi-current system, enact a design requirement to keep current in DC.

- As newly appointed Avionics & Control Lead, come up with a streamlined engineering design process and engineering practices.