Project Overview

As the Blue Ghost Lunar Lander reaches a point where it needs to be Environmentally Tested at NASA, we were in the process of closing out tickets and critical action items before it would be sent out. One of these items was to run a Landing Case simulation to ensure all the valves would actuate as intended and the simulations would reflect a successfuly landing burn. The issue was that the Reaction Control System valves would overheat to around 350 degrees celsius very quickly when ran without propellant. This made testing difficult.

Your Role and Contributions

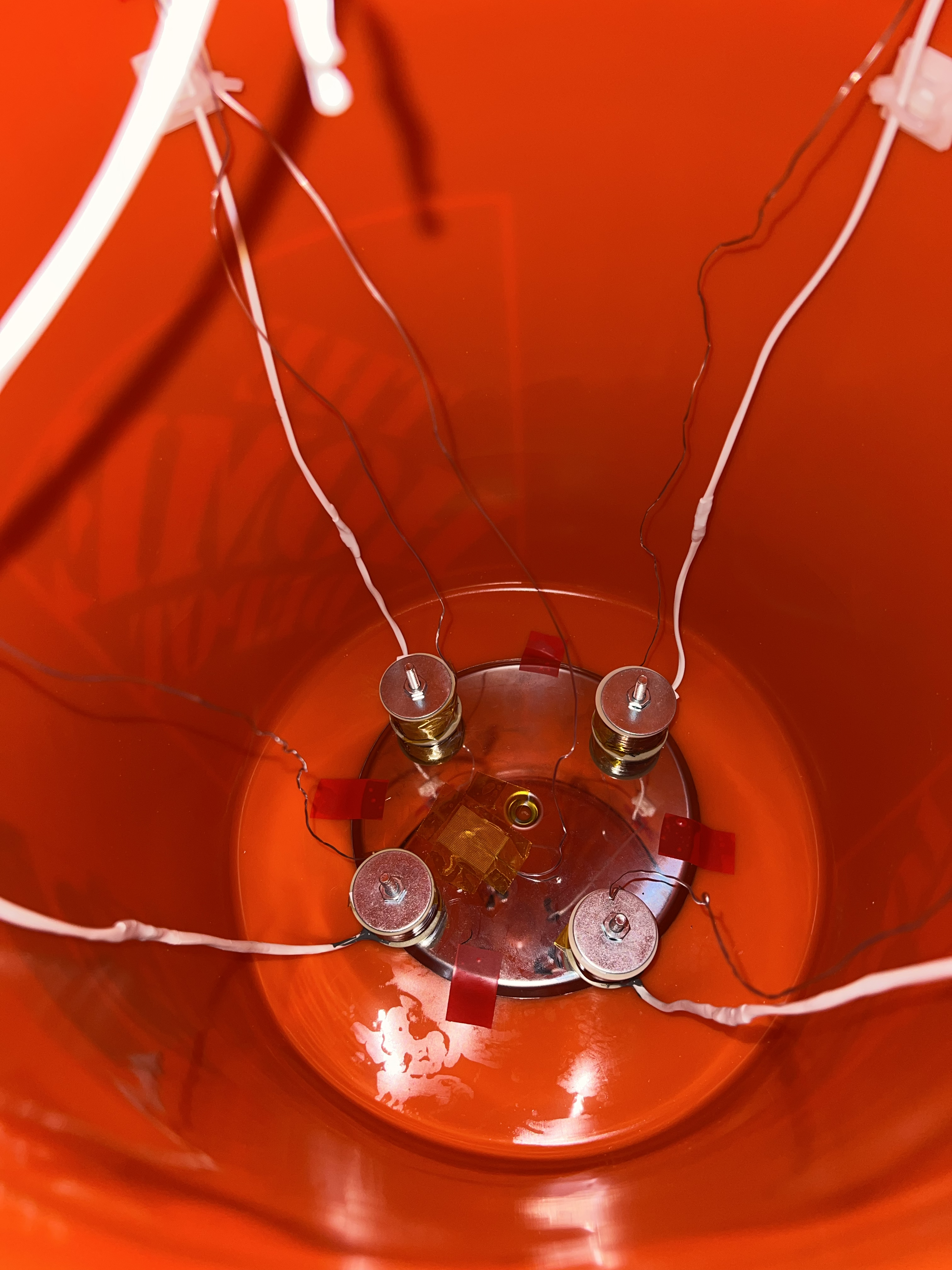

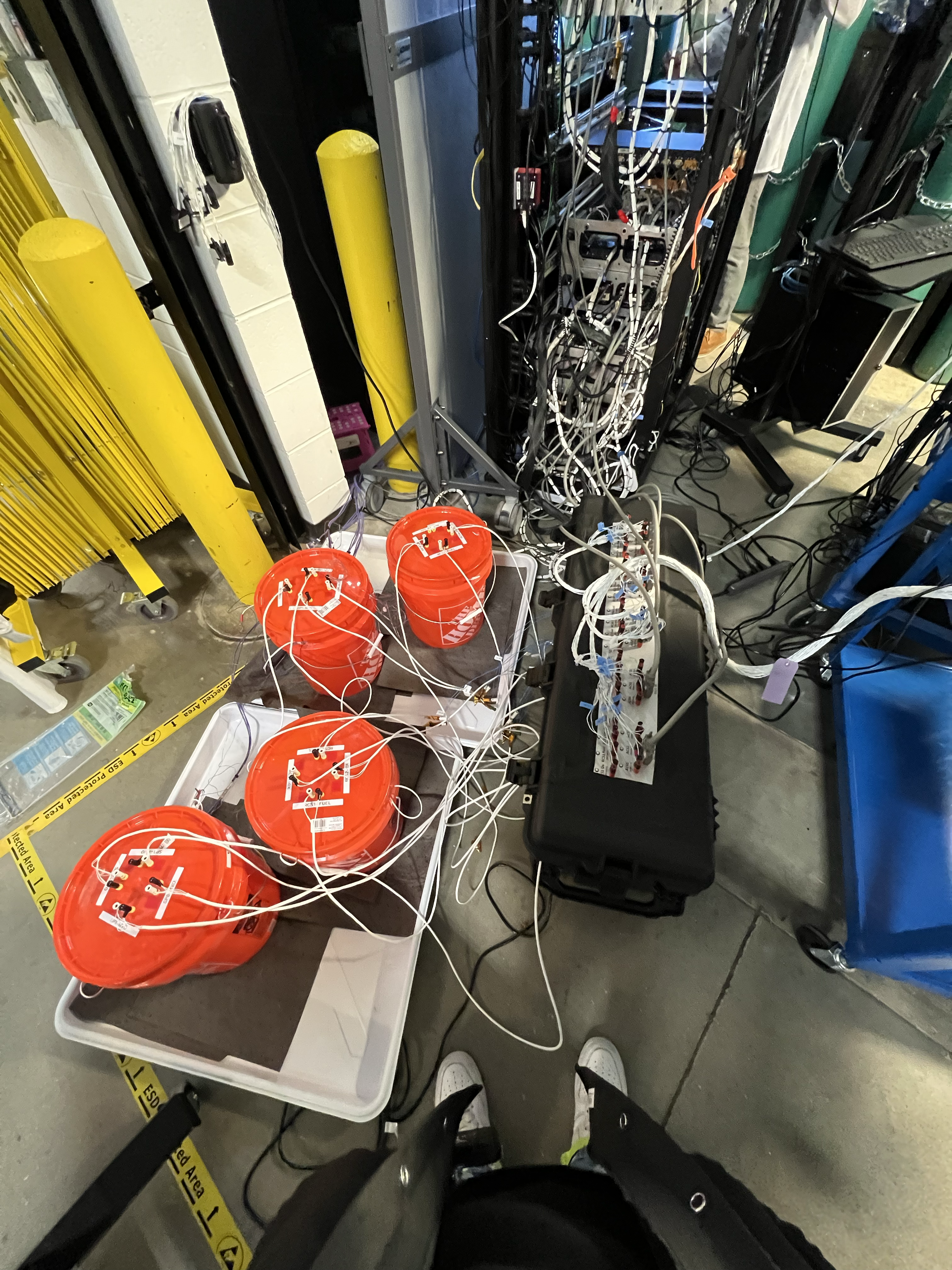

- One of my summer projects was to design and implement a solution in which the valves would not overheat and could run the Landing Case Simulation. I successfully implemented a water-cooling solution, dubbed "Valve Soup". This involved placing 4 solenoid coils (valves) inside a bucket of 3 gallons of distilled water. This would keep the valves running at around 100 degrees celsius and would integrate well with the existing connections to our Avionics Simulation Rack. There would end up being 4 buckets for 16 coils which made up the Reaction Control System.

- I upgraded the existing main engine and attitude control system valve simulation test bed to a high-fidelity valve rack testbench which employed the use of real valves (as opposed to model loads) to get accurate power consumption data comparable to the real lander. The rack would also have DAQ interface capabilities, valve control, and visual feedback through LEDs.

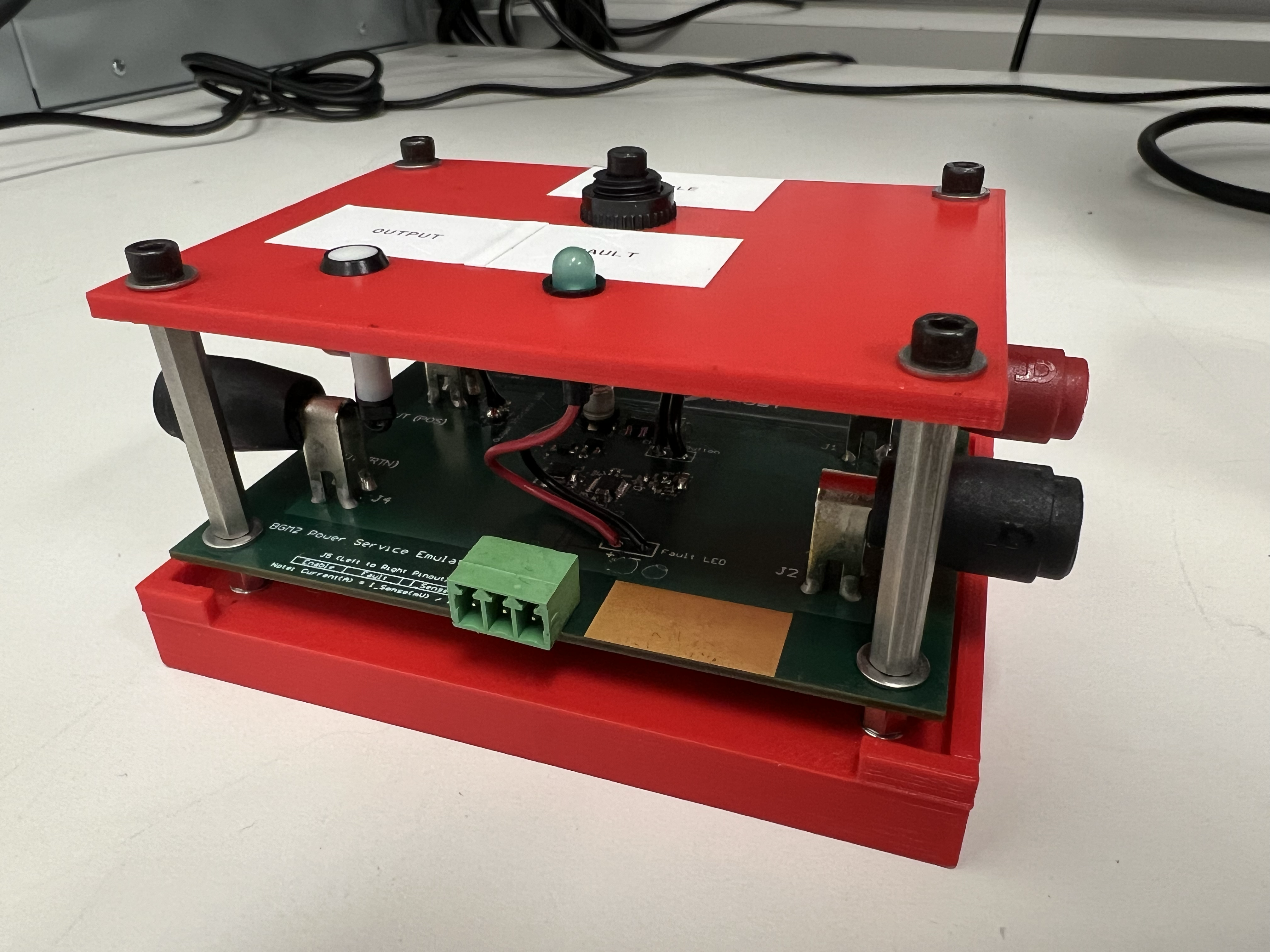

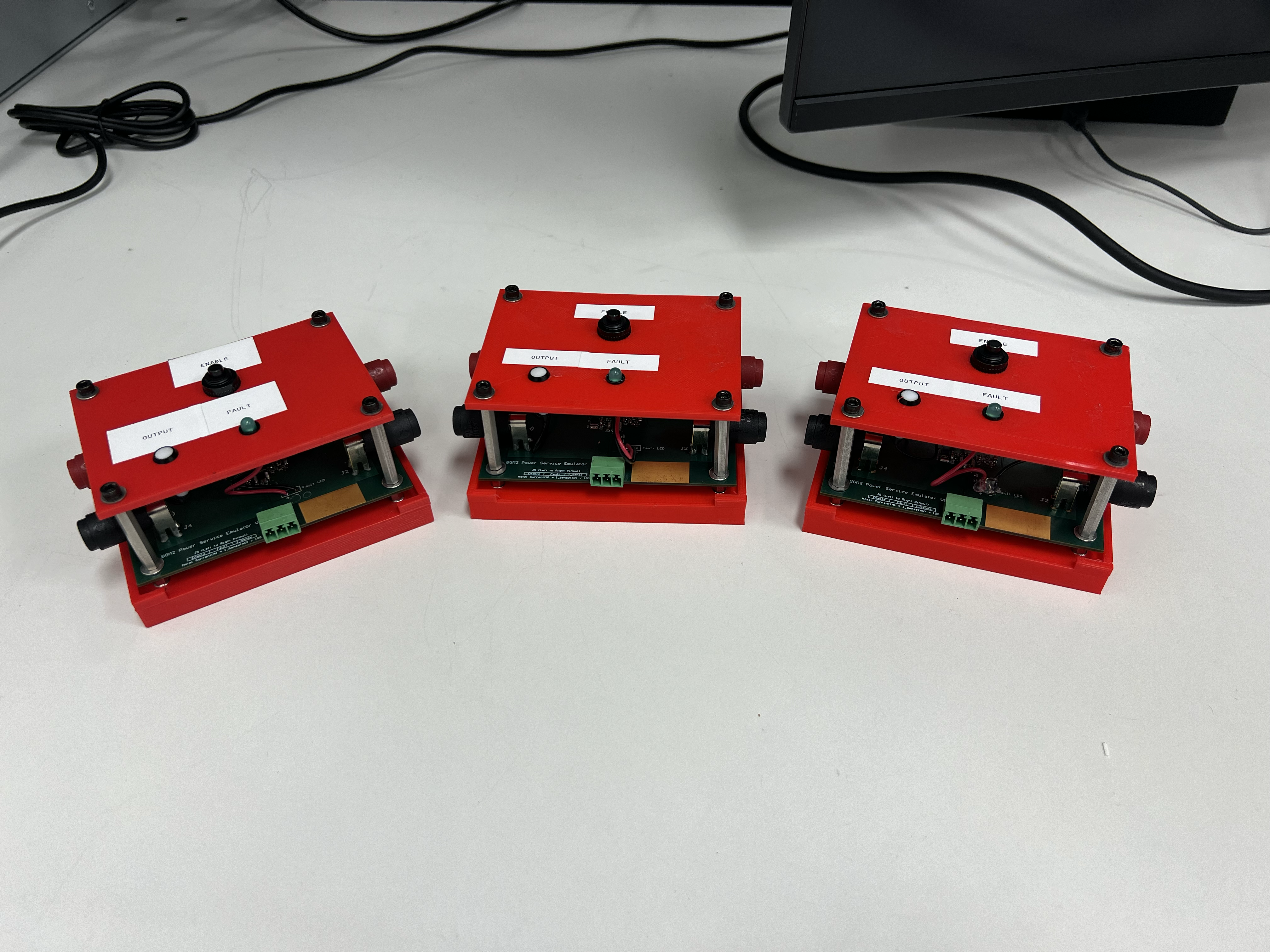

- A side project I did was solder, test, and validate surface-mount-component power emulators which payload customers would be able to use for testing their payload with Firefly hardware.

Skills and Tools

- Heat Tranfer Basics

- Fluid Flow

- Mechanical Control

- Altium

- Circuit Analysis

- Lab Tools (Electronic Load, Power Supply, Oscilloscope, NI CDAQ, Multimeter)

- Surface-Mount Soldering

- Surface-Mount Circuit Inspection and Debugging

- Python Programming

- Iterative Design

- Presentation

Goals and Objectives

- Find a solution to prevent valve over-heating

- Solder and debug power emulators for payload customer use

- Design and build a high-fidelity valve simulator testbench

Outcomes and Achievements

Visual Aids

Single bucket with 4 solenoid coils (filled with distilled water)

A single power emulator with overcurrent light, actuation button, and visual feedback LED

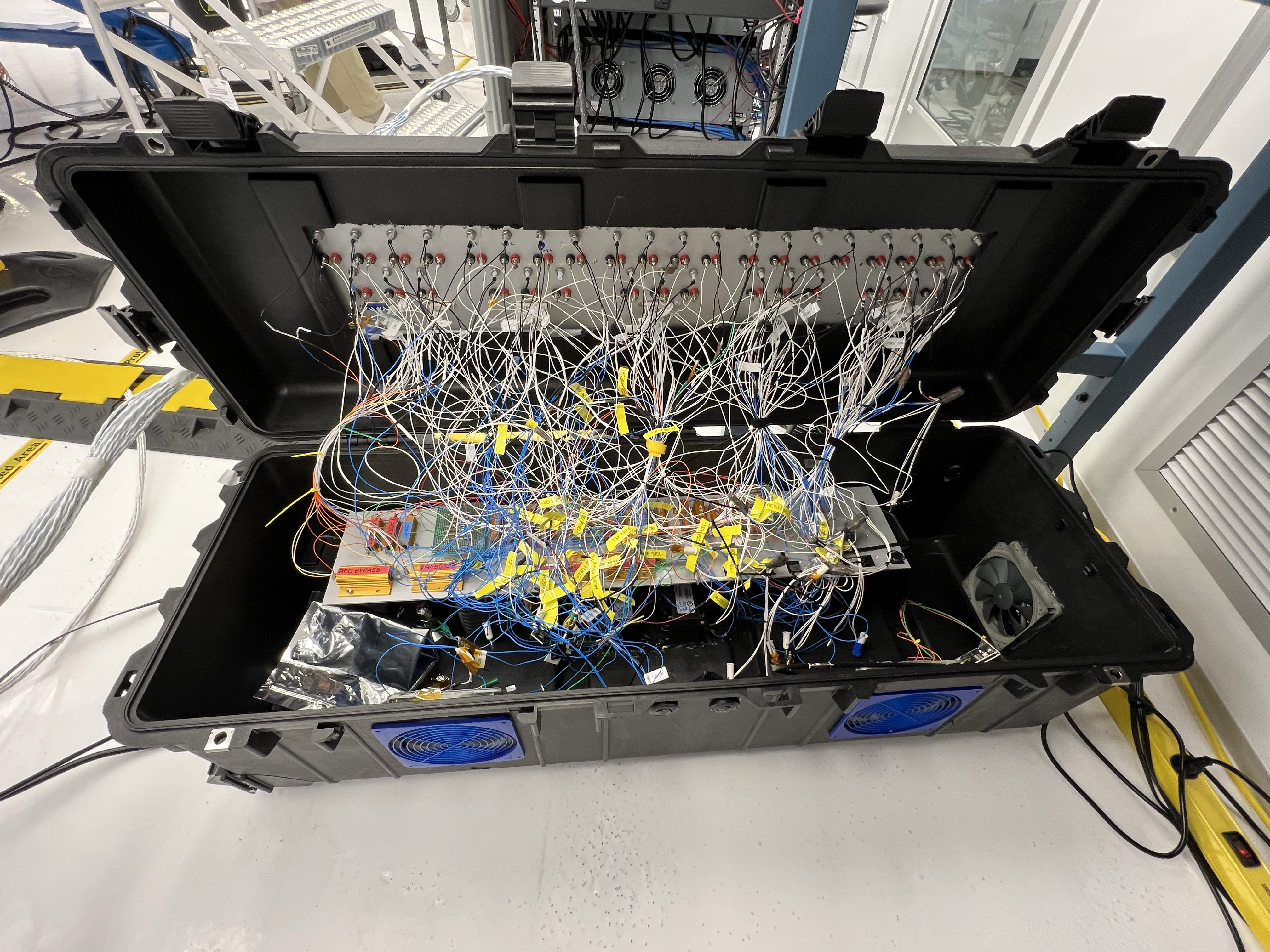

Old valve simulation pelican case, integrating with NI CDAQ and avionics control systems

Integration of buckets with the old valve sim box and avionics rack

Three power emulators I made

Front of my upgraded high-fidelity valve rack simulation testbench, 12 ACS valves on the blue panel, 6 CDAQ circular connectors on the blue panel, LEDs on the black panel for every valve, 6 main valves mounted on the top at the back, a container with reservoir and pump to circulate water and run 16 RCS valves, avinoics connectors on the back left

Lessons Learned and Technical Takeaways

- I learned about how to think about heat transfer and relevant equations which would aid in my obtaining a solution for the over-heatig issue

- There has to be extensive testing and data analysis before a final solution is obtained and validated

- It is important to not get stuck in analysis paralysis and test as many ideas as possible

- Just because a manufacturer has nominal values of components in a datasheet, doesn't mean there are inconsistencies, always double check values of components

- The test setup is important, always understand what the circuit and test setup is doing and that the results make sense